Lithium-Iron-Phosphate (LFP) batteries are popular for camper van electrical systems and they have a number of advantages for this application. But, they do have one disadvantage, which is that they cannot be charged at temperatures below 32F. LFP batteries suffer permanent damage when they are charged at temperatures below 32F.

Some of the newer LFP batteries have built in heaters that bring a cold battery up to 32F before they allow charging. This is probably a good way to go if you plan to use the van in cold weather. My LFP batteries are made by SOK and when I bought them, they did not offer heaters, but the new ones do and the price increase is not large.

The material below goes into one way to heat up cold LFP batteries to the point where it is safe to charge them.

We want the heating system to address these cold conditions…

- We want to leave on a winter trip, and the van has been cold soaking in the driveway for days – maybe down as low as -10F. How do we heat the battery up enough so that it takes a charge on the drive out to the campsite.

- On a road trip in the van, we want to stay in a motel overnight, and its cold. We need a way to heat up the battery in morning within an hour or two.

- We want to leave the van for a day of skiing or whatever. We need a way get the battery back up to temp when we get back to the van.

- We are 0vernighting in the van and its very cold out – we are heating the van to 50F for the overnight sleep period. The battery compartment runs colder than the van interior, how to make sure the battery compartment stays above 32F?

We want a heating system that is simple, reliable, cheap and that does not waste a lot of energy. For me, leaving the van furnace on or a space heater on to heat up the whole van for long periods of time just to keep the battery up to temperature is not something I want to do. If you leave the furnace on, it could malfunction, and using either a fossil fuel furnace or an electric heater on is wasteful and adds CO2 pollution to the air.

We are going to try the two pronged system described below.

Battery Compartment Fan

I did a test earlier in which I logged the van interior temp, battery compartment temp, and outside temp on a cold night. For our van, the battery compartment temp ran about half way between the van interior temp and the outside temp. So, if its (say) -10F outside and 50F inside, the battery compartment is going to get down to 20F – so, even with the van interior heated to a comfortable level, the battery compartment can still go below 32F depending on your van layout. The idea of the little fan detailed below is to get the battery compartment temperature closer to the van interior temperature.

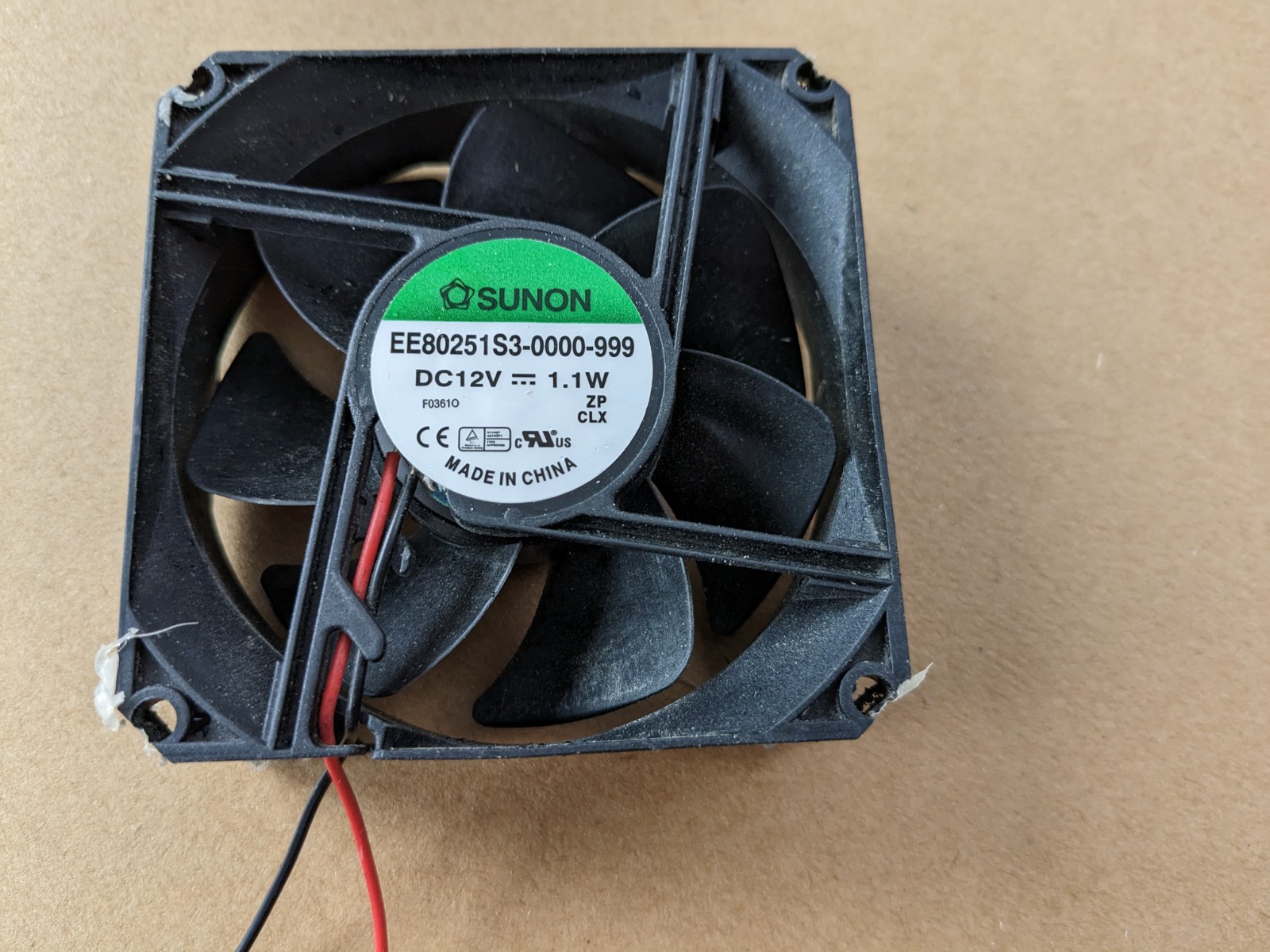

We are adding a small 12 volt computer fan in the wall of the battery compartment that faces the van interior. When the fan is on, it blows warm air from the van interior into the battery compartment. The fan is small and quiet and only uses 1.1 watt (0.1 amp) – so, it can be left on for long periods without worrying about battery drain.

Our battery compartment is leaky enough so that the air has places to exit without a dedicated exit vent.

Under Battery Heater Pads

The other part of the solution is to add a 12 watt silicone heater pad under each of our two batteries. The heater pads are sized such that in cool or cold weather they can be left on indefinitely without overheating the battery, so they do not need a thermal control system, just an on/off switch.

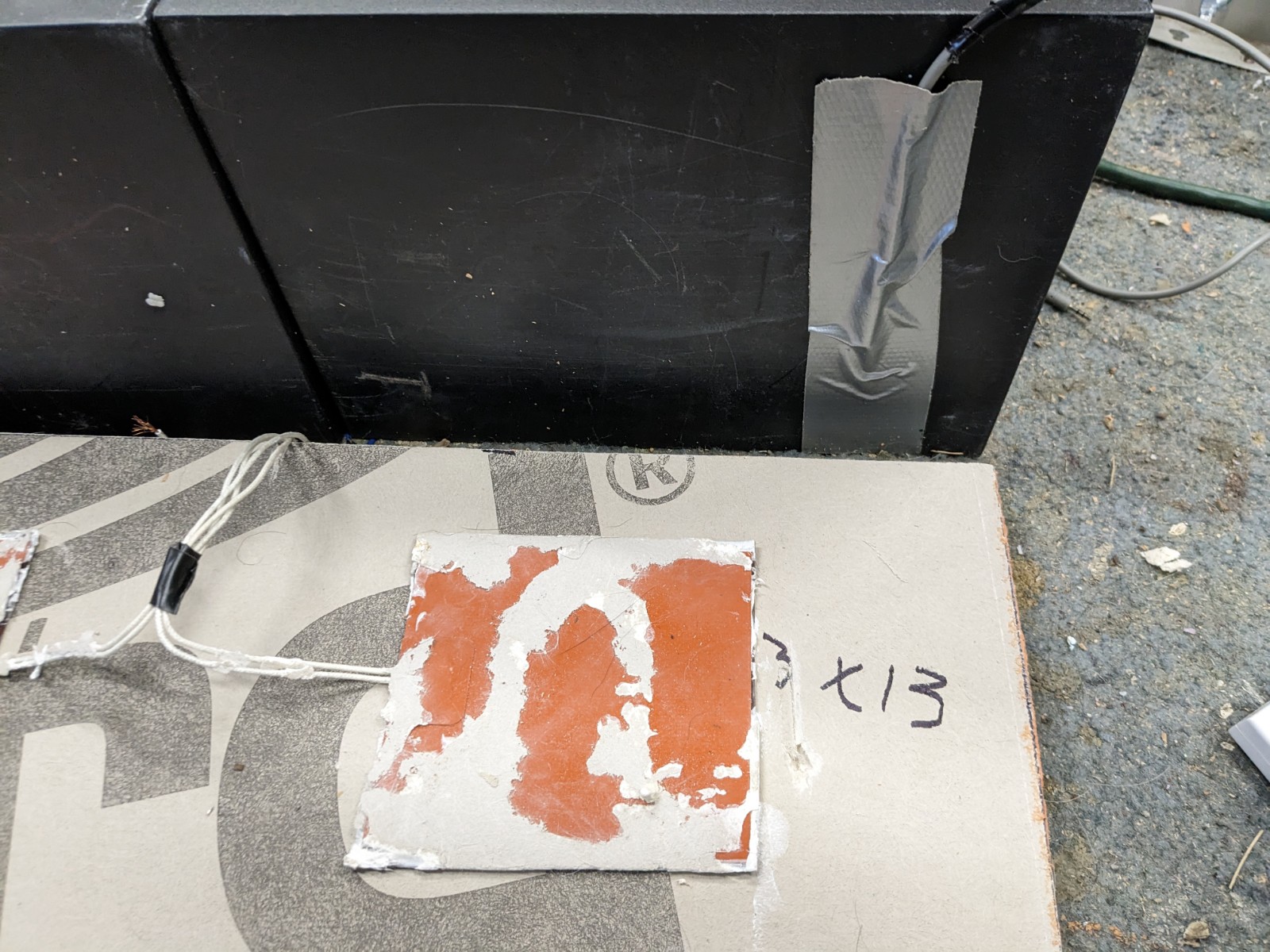

This picture shows the heater pad running in free air just to see what the maximum temperature it gets to. About 120F maximum. These heating pads are sold for the purpose of heating bee hives in cold weather. The aim was to get a heater pad wattage that would keep the batteries warm even in very cold temps and would bring a cold soaked battery up to 32F in a couple hours, but low enough in wattage that it would not overheat the battery if left on continuously in weather around 32F.

The picture above shows the silicone heating pad installed in the battery compartment. It shows multiple colors because in a previous experiment it had some paper siliconed to it and I could not get it all off – normally it would be all orange. The logger temperature sensor is taped to the bottom of the battery compartment near the heating pad. The other LFP battery is still in place (the black box at top of picture).

The bottom of the battery compartment where it sits on the van floor is insulated with 1 inch Polyiso, and the side of the battery compartment that faces the van sidewall is insulated with Thinsulate. The top of the battery compartment will probably be insulated in the winter.

Normally, the fan and heater pads are powered by our two LFP house batteries. This is OK even in cold temps because even when its too cold to charge the batteries, it is safe to draw current from them. The two heaters pads and fan draw about 2.2 amps when running, so running them over a 12 hour night only draws about 26 amp-hrs out of our 200 amp-hr pack.

I’m in the testing mode right now to make sure the system works, and I’ve been just hooking the heater pads directly to the LFP batteries. If the system looks workable after the testing, I’m going to hook the heater pads up using a 12 volt connector that can just be hooked up when the heater is needed. There will be an inline fuse in the heater supply wires.

I believe that I had one case on a very cold night (-20F?) in which the BMS completely shutdown our SOK batteries such that I could neither charge or draw power from it. I took the batteries inside to warm them up, and once they warmed up, the returned to normal. Given that this happened, I will carry a small jumper wire that allows me to hook up the heater pads to the van starter battery to heat the LFP batteries up even if the LFP battery BMS has completely shut down the battery.

Testing the Heater System

I have been doing some testing of the heater system to verify that it would operate as expected – results below.

Test 1: Heater Pads Running Over a Cold Night

This is a test run in the van over a cold night without heating the van. The LFP batteries were heated with the 12 watt silicone heater pads – one for each battery.

A temperature sensor was mounted on the bottom of the battery case about half an inch away from the edge of the heater pad. A 2nd temperature sensor was taped to the top of the battery. The SOK batteries have a metal case, so they probably conduct heat better than plastic cased batteries and may distribute the heat more evenly. A 3rd temperature sensor was placed outside the van to measure the ambient temperature. The van interior was not heated.

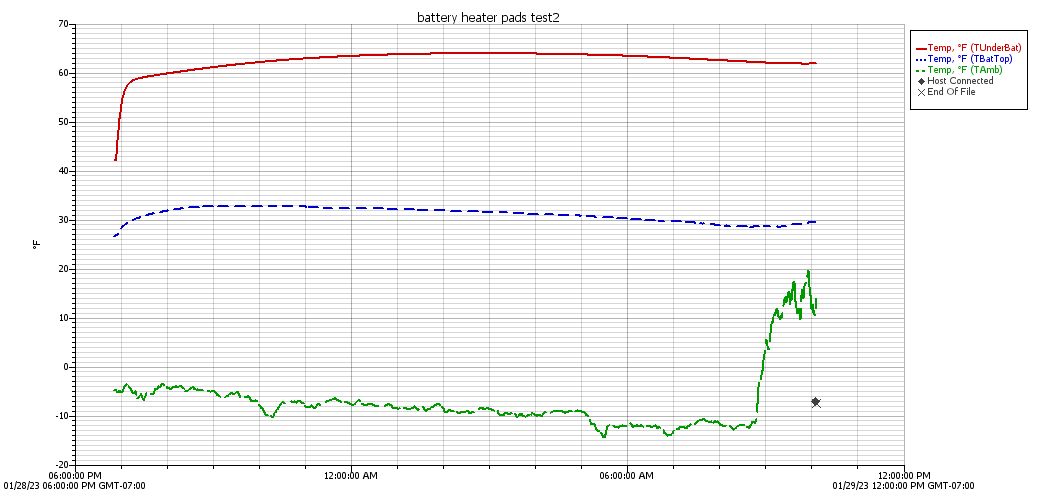

The red line is the temperature of the bottom of the battery case near the heater pad.

The blue line is the temperature of the top of the battery case.

The green line is the ambient outdoor temp at the van location.

The test runs from 7 pm on the 28th to 10am on the 29th. At the start of the test, the outdoor temp is -5F, and the batteries are at about 35F (they start warmer than ambient because of a previous test).

The outdoor temp drifts slowly down from -5F to -12F in the morning. The spike in the outdoor temp at the end is due to the sensor being located in the sun.

The heater pads keep the average battery temperature well above 32F for the whole night even on this very cold night, so I think they are OK for a situation in which we plan to leave on a trip in the morning and plug the heaters in the night before. It would have been nice if the batteries had been cold soaked all the way down to -5F to see how fast the heaters bring the temp up, but it looks like the warm the batteries fairly fast.

There is no tendency to overheat the batteries, and even if the outside temp is warmer (say in the 20’sF), it looks like the batteries would not be overheated by the heater pads being on all night.

Test 2: Running the Fan to Heat the Battery Compartment

This is a test to see if the little fan can boost the temperature in the battery compartment to get it closer to the van interior temperature than the outside ambient temperature.

Coming in a few days.

Test 3: A Shop Test of the Heater Pads With and Without Insulation

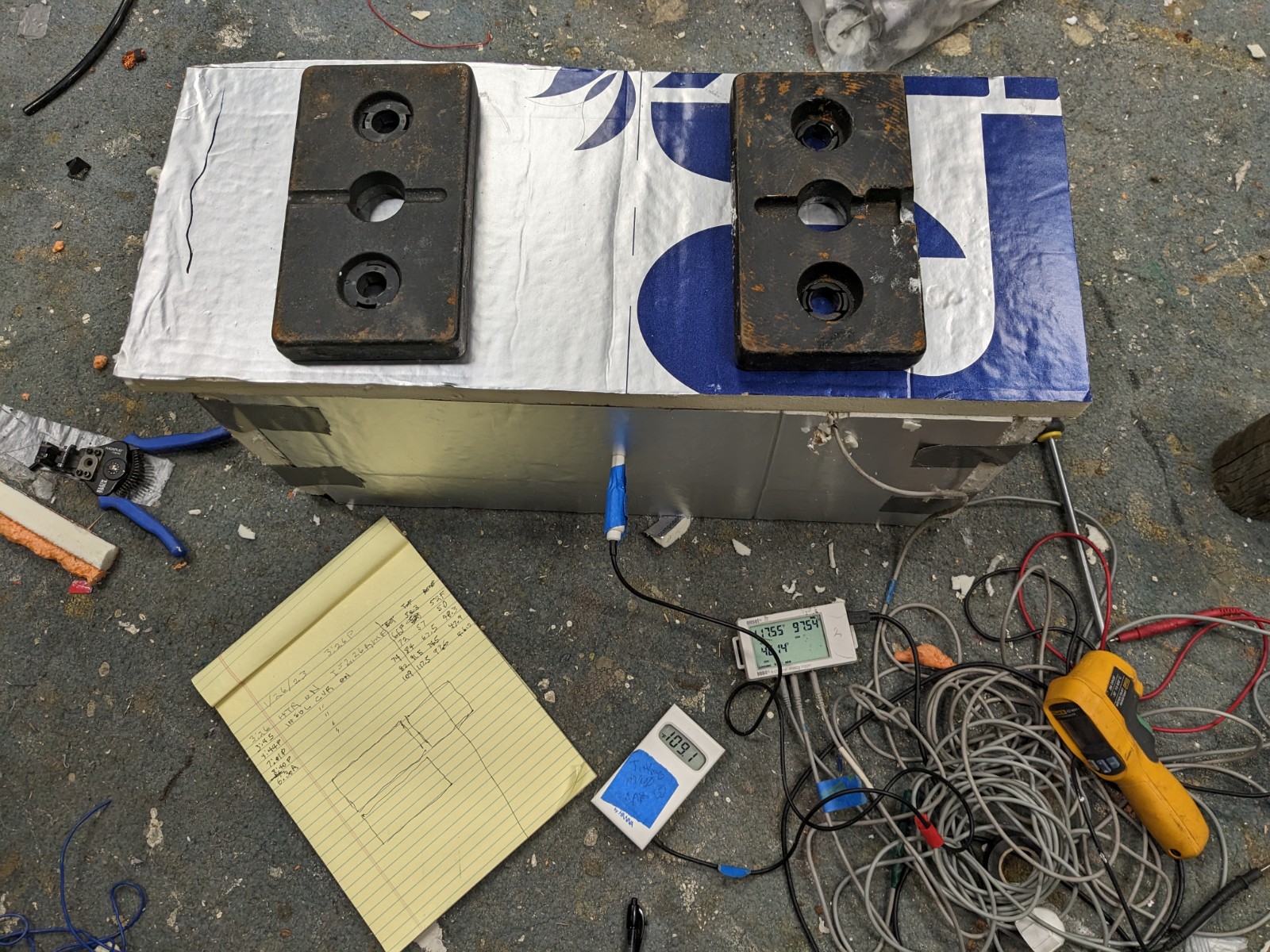

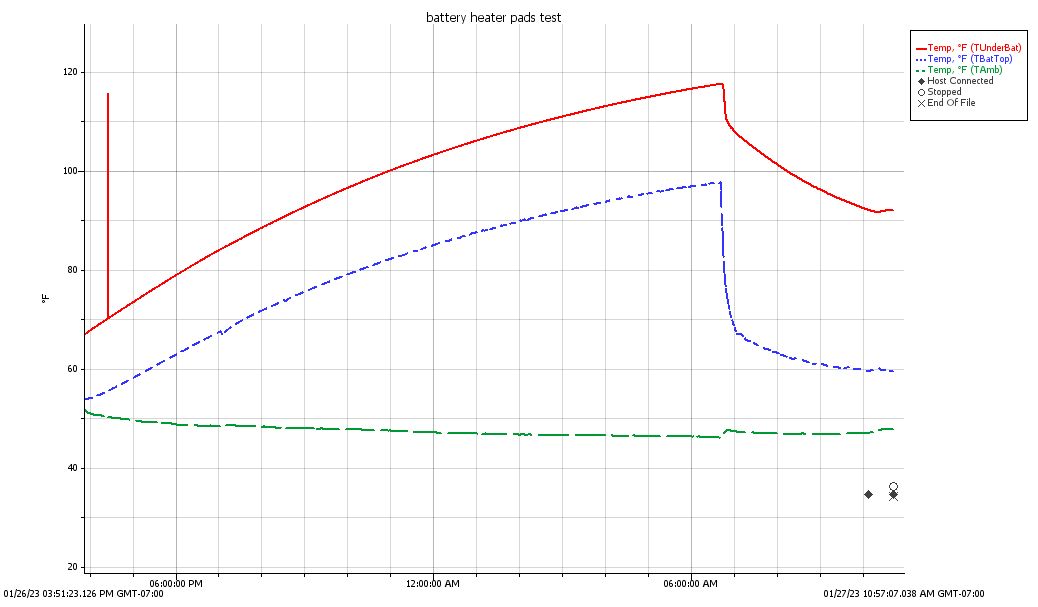

I ran this test in the shop before the one above just to get some idea on whether the heater pads had any tendency to overheat the battery, especially if the battery was in an insulated compartment.

In the end, I think it makes sense to insulate the faces of the battery compartment that face the outside – eg the floor and the wall that faces the sidewall of the van. Without insulation on these faces, the battery compartment will lose a lot of heat to the outside and tend to run at a temperature closer to the outside ambient rather than the temp of the interior of the van. It probably makes sense not to insulate the other faces of the battery compartment in that it will just cause the battery to heat up more when you are pulling heavy loads from it due to the batteries internal resistance and to the battery heater pads.

This is the insulating pad (1 inch Polyiso) that the batteries sat on with the two heater pads glued in place. The heater pads look odd because I used them in an earlier test where they were glued to a heavy paper and I could not get all the paper off.

The two SOK LFP batteries in an insulated box. A temperature sensor was placed on top the battery case and on the bottom of the battery case near the heater pads.

Battery fully enclosed in insulation.

The red line is the temperature on bottom of battery near heater pad.

The blue line is the temperature of top of battery case.

The green line is the ambient shop temperature

Over about 14 hours, the bottom of battery case temperature goes up from about 68F to about 118F, and is still rising at end of test. The battery cells are separated from the case with some neoprene, so they likely did not quite get up to 118F, and the shop temperature was high enough that you would likely not have the heater on at all. But, it looks like with a fully insulated battery case, the battery could get a bit warmer than you would like, if the heater is on for a very long time in not so cold conditions. So, probably best not to fully insulate the battery – probably best to only insulate the parts that face the outside (floor and van wall). And, not a bad idea to have a temperature monitor on the battery case.

At the end of this test, I quickly took the insulation off and then measured the temperature of the case in many places on the top and sides using an IR thermometer. It was pretty uniform, with temperatures ranging from 89F (corner of top) to 101F (near bottom side). Almost all of the temps were in the 90’sF. This is good, I guess, as its probably not good for the battery to have big temperature variations within it. The SOK metal case may help some in this regard.

Gary 1/28/23