New Electrical Section

This is an old page that covers the original electrical system we had in the van. In 2021 we installed a new electrical system, which is described in detail here…

We have left this page for old times sake, but if you are starting a new electrical system, use the new electrical system pages.

This section goes over the design of the electrical system for the camper conversion, the selection of components, and the installation.

Back to the ProMaster camper van conversion main page…

This section goes over the design of the electrical system for the camper conversion, the selection of components, and the installation.

Back to the ProMaster camper van conversion main page…

| Safety Warning and Disclaimer |

There are serious safety issues involved with wiring your own system. The voltages are high, and potentially lethal. Doing the system incorrectly can lead to serious consequences down the road.

PV systems have the added hazard that even when the grid power is turned off, the system can be “live” and present a serious shock hazard.

If you don’t feel like you want to put in the time to learn how to do this correctly, then find an electrician that you can partner with to do this part.

I want to make it very clear that I am not an electrician, and I take no responsibility whatever for the correctness of the wiring hints below — you need to do your own homework!

http://www.builditsolar.com/Contact/legal.htm

Overview

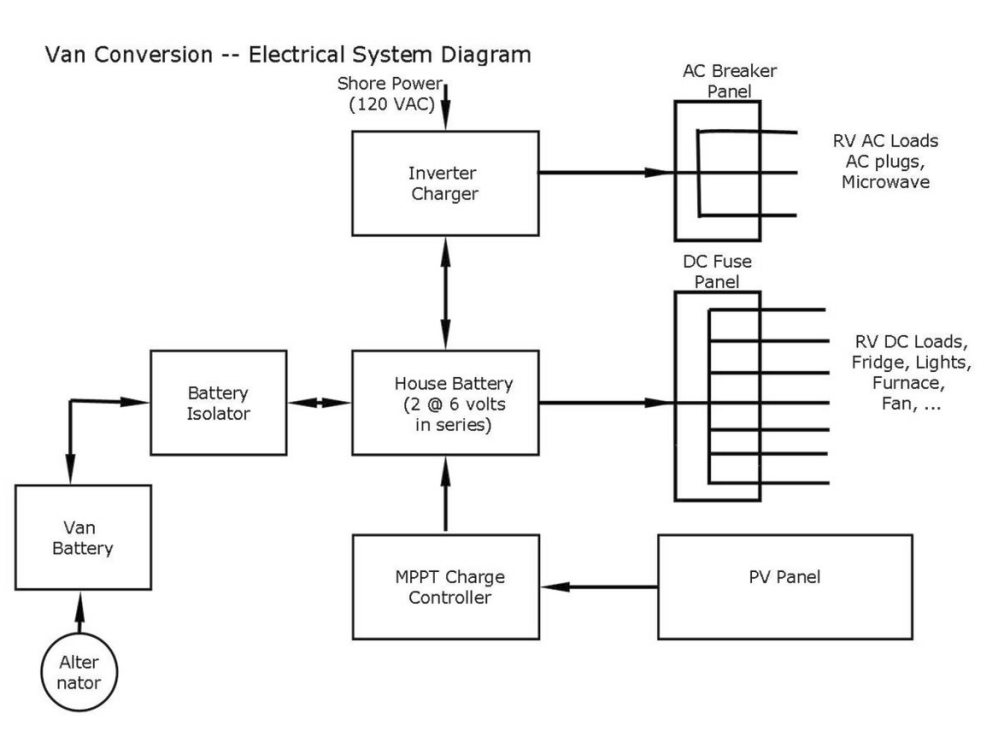

We do not want to be tied to electrical hookups at RV parks, so we incorporated a good sized house battery and tried to minimize our electrical loads. Most of our loads are DC and run directly off the house battery with only a couple of modest AC loads that can be powered either by our onboard inverter or shore power. The house battery can be charged from the van alternator, or from a large solar panel on the roof, or from shore power if available. The battery can supply a couple of days (or more) with typical loads, and on a sunny day, the solar panel is sized to fully recharge a depleted house battery. At this point (Jan 2017) we have used our van for about 2 years and the electrical system has performed well without any significant problems. 2019 Update: Our 2014 ProMaster van now has 70K plus miles on it with many trips. The electrical system has performed well, and no significant changes have been needed. We did add a Victron Battery Monitoring system just to have better visibility of how the batteries are doing — a nice gadget to have, but definitely not a necessity. At the heart of the camper electrical system is the house battery. It can receive charge from three separate sources: 1) the van alternator when the engine is running, 2) the roof mounted solar panel, and 3) the inverter/charger when plugged in to shore power.

The house battery powers all of the DC loads (like lights, fridge, furnace fan, water pump) via the DC distribution panel. It also powers an inverter to provide 120 Volt AC house power to our small number of AC loads. Most of the electrical devices on the van run directly from the 12 volt house battery.

The Battery Isolator prevents the RV loads from running down the van starting battery, the PV panel charges the house battery via the Charge Controller, the DC and AC distribution panel safely distributes power to the RV electrical loads, the Inverter/Charger supplies 120 AC power from the house battery and also charges the house battery when hooked up to shore power.

All of this explained in much more detail below.

At the heart of the camper electrical system is the house battery. It can receive charge from three separate sources: 1) the van alternator when the engine is running, 2) the roof mounted solar panel, and 3) the inverter/charger when plugged in to shore power.

The house battery powers all of the DC loads (like lights, fridge, furnace fan, water pump) via the DC distribution panel. It also powers an inverter to provide 120 Volt AC house power to our small number of AC loads. Most of the electrical devices on the van run directly from the 12 volt house battery.

The Battery Isolator prevents the RV loads from running down the van starting battery, the PV panel charges the house battery via the Charge Controller, the DC and AC distribution panel safely distributes power to the RV electrical loads, the Inverter/Charger supplies 120 AC power from the house battery and also charges the house battery when hooked up to shore power.

All of this explained in much more detail below.

Components:

These are our choices for the main components.

Item Description Cost House Battery 2 @ 6 volt, 200 AH golf cart batteries (Costco) $180 Inverter/Charger Triplite APS 1250 Inverter/Charger $406 Battery Isolator PAC-200 Battery Isolator 200 amp $46 MPPT Charge Controller Midnite Solar KID Charge Controller $280 AC/DC Distribution Panel PD5000 AC/DC Power Control Panel $58 PV Panel SolarWorld SW315 PV panel $368 Total (not including fuses, wire, …) $1338

Batteries

We used two 220 amp-hr, 6 volt golf cart batteries from Costco connected in series for 12 volts. This gives us some reserve for cloudy days.. We thought about using an AGM battery, the advantages of the AGM battery is that it does not need water to be added (low maintenance), it vents less hydrogen during charging than a flooded battery, and there is no chance of spillage.. On the down side, they are quite a bit more expensive for the same capacity, and appear (from the Trojan Battery data below) to have a shorter life. The conventional flooded lead-acid golf cart batteries we used are less expensive and very readily available, but will require checking the water levels from time to time, and the battery compartment will have to be vented to the outside to prevent hydrogen buildup. But, flooded batteries vent very little hydrogen when charged at the correct rate. Just as an approximate comparison — some data on two of Trojan Batteries offerings of flooded and AGM batteries.| Type | Model | Volts | amp-hr (20hr) | Len | Wid | Ht | weight | Cycles (80% discharge) | Cost/bat | |

|---|---|---|---|---|---|---|---|---|---|---|

| Flooded | T-105 | 6 | 225 | 10.3 | 7.11 | 11.07 | 62 | 750 | $110 | |

| AGM | 6V-AGM | 6 | 200 | 10.3 | 7.08 | 10.74 | 65 | 500 | $295 | |

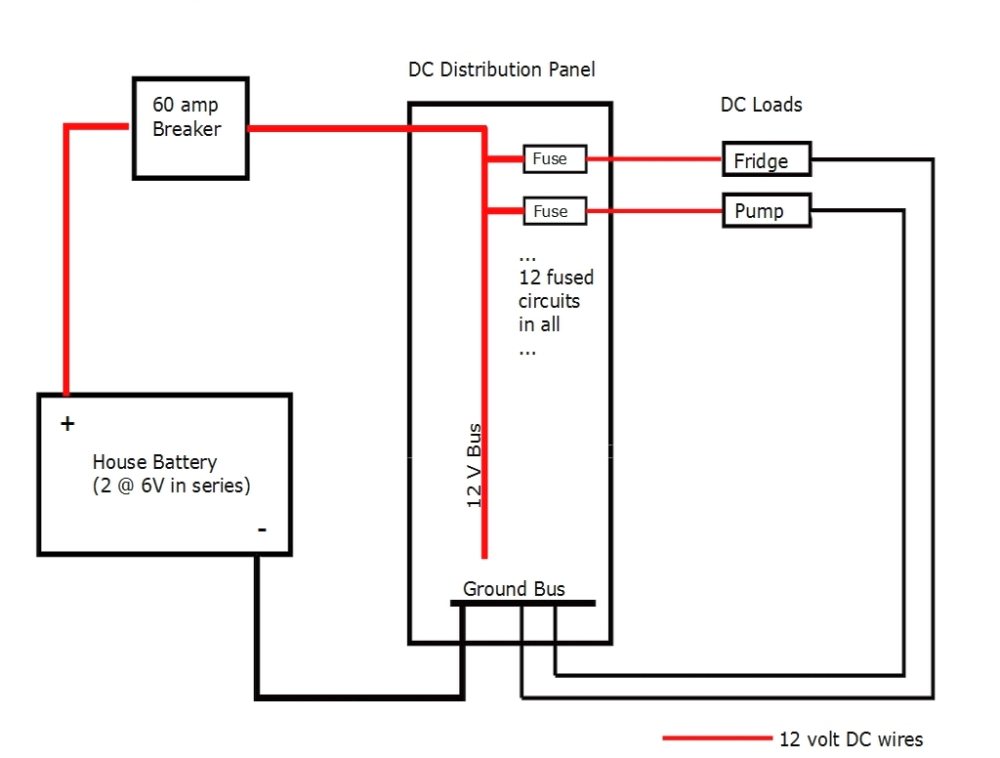

AC and DC Distribution and Fuse Panel

After quite a bit of looking around, I found this nice and not very expensive distribution panel for RV’s that handles both the AC and DC distribution in one fairly compact package. It provides for up to 12 DC circuits and up to 4 AC circuits. This looks like another good option for a combined AC and DC distribution panel…

This looks like another good option for a combined AC and DC distribution panel…

Battery Isolator

This gadget allows the van alternator to be used to charge the house battery, while preventing the van starting battery from being drained by powering loads in the RV. It isolates the van starting battery from the house battery when the ignition switch is off so that RV loads only discharge the house battery. The idea is that even if you discharge the house battery overnight, the van starting battery will still be fully charged. This relay based unit appeals to me because: 1) it does not have the voltage drop that the diode based isolators do, 2) it does not get wired between the alternator and the starting battery as the diode ones do (so less interference with the van wiring), and 3) It is easy to hook up because it just needs a wire from the starting battery and an 12V source that goes on with the ignition switch.

Not sure if I’m reading this right, but it seems like when you start the van that this unit puts the starter battery in parallel with the house battery. I guess this could be good if your starting battery is low, but maybe not so good if your house battery is low?

In hindsight, a unit with a lower amperage rating would have been fine. The unit is inline with a 50 amp circuit breaker, so anything over 50 amps would probably be fine. The maximum recommended charging current for the golf cart batteries is about 30 amps.

Another option would be to use a Voltage Sensing Relay. This is a relay similar to the one above, but the relay is activated just monitoring the van battery voltage to determine if the engine is running or not. It requires less wiring.

This relay based unit appeals to me because: 1) it does not have the voltage drop that the diode based isolators do, 2) it does not get wired between the alternator and the starting battery as the diode ones do (so less interference with the van wiring), and 3) It is easy to hook up because it just needs a wire from the starting battery and an 12V source that goes on with the ignition switch.

Not sure if I’m reading this right, but it seems like when you start the van that this unit puts the starter battery in parallel with the house battery. I guess this could be good if your starting battery is low, but maybe not so good if your house battery is low?

In hindsight, a unit with a lower amperage rating would have been fine. The unit is inline with a 50 amp circuit breaker, so anything over 50 amps would probably be fine. The maximum recommended charging current for the golf cart batteries is about 30 amps.

Another option would be to use a Voltage Sensing Relay. This is a relay similar to the one above, but the relay is activated just monitoring the van battery voltage to determine if the engine is running or not. It requires less wiring.

Inverter/Charger:

The inverter/charger performs two jobs. When you are not hooked up to shore power and are being powered by the house battery, it provides limited 120 volt AC power for the van from the house battery. When you are hooked up to shore power, it turns off the inverter function and passes the shore power through to the AC loads that are connected to the inverter, AND it charges the house battery using a full 3 stage charger. We selected the Tripp Lite APS1250, which provides 1250 watts of AC from the battery, and when in charger mode, provides up to 30 amps of battery charging using a 3 stage charger. These inverter chargers are made by several companies. I chose the Tripp Lite mostly because I have a larger one I bought several years ago and it has held up well.

I like this kind of inverter/charger because: 1) it eliminates the need for a separate battery charger to charge from shore power, 2) it has 3 stage charging, so its easy on the battery, 3) it automatically switches from the inverter powering AC loads to the shore power when you plug into shore power, so you can hook your AC loads up to the inverter and they will be powered whether you are on shore power or on house battery power.

Like most of these inverters, it draws some power from the battery whenever the inverter is turned on even if nothing is plugged into the inverter, but it can easily be turned off manually when no AC power is being used, so this is a nuisance, but not a serious one.

Update 1/1/2016: One thing I’ve noticed is that pure sine wave inverter/chargers have dropped in price some, so if you plan to run AC loads that might need the pure sine wave output, you might want to upgrade to a pure sine wave inverter — one example is the Xantrex Freedom HFS 2000 Inveter Charger.

These inverter chargers are made by several companies. I chose the Tripp Lite mostly because I have a larger one I bought several years ago and it has held up well.

I like this kind of inverter/charger because: 1) it eliminates the need for a separate battery charger to charge from shore power, 2) it has 3 stage charging, so its easy on the battery, 3) it automatically switches from the inverter powering AC loads to the shore power when you plug into shore power, so you can hook your AC loads up to the inverter and they will be powered whether you are on shore power or on house battery power.

Like most of these inverters, it draws some power from the battery whenever the inverter is turned on even if nothing is plugged into the inverter, but it can easily be turned off manually when no AC power is being used, so this is a nuisance, but not a serious one.

Update 1/1/2016: One thing I’ve noticed is that pure sine wave inverter/chargers have dropped in price some, so if you plan to run AC loads that might need the pure sine wave output, you might want to upgrade to a pure sine wave inverter — one example is the Xantrex Freedom HFS 2000 Inveter Charger.

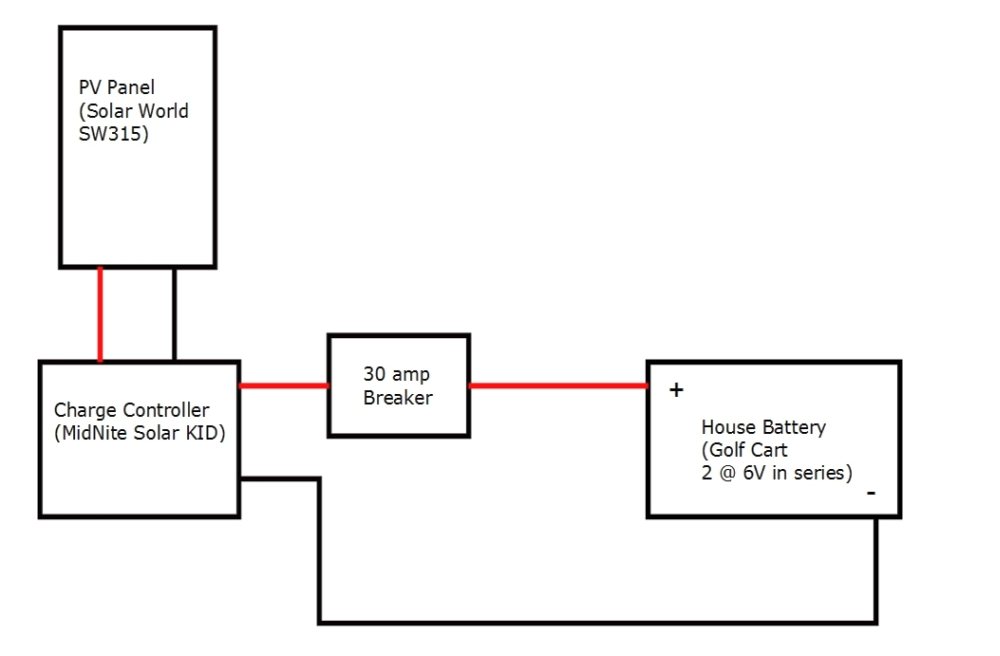

Solar Charge Controller:

The charge controller goes between the PV panel and the house battery. It transforms the PV panel output voltage down to a voltage that is suitable for charging the battery, and it prevents the solar panel from overcharging and damaging the battery. I am using the MinNite Solar KID charge controller. This is a relatively new design that has quite a bit of flexibility for small solar systems. It includes MPPT (Maximum Power Point Tracking) which is more efficient than the PWM models. The unit is very nicely made in the US. The manual is written in an informative and down to earth style that is refreshing compared to the awful manuals that come with so many products. I’m told the phone tech support is very good. The unit includes basic monitoring of the system, and they sell an add on unit for more extensive monitoring if desired. Midnite Solar has a nice online tool that lets you see if the PV panel(s) you are planning to use are compatible with the KID. Price is about $285.Update: March 4, 2015: They have just raised the price up to $440. I think that this is kind of steep, and I’d probably look for a better option. Further update: see the comment by Dennis below for a less expensive Victron option.

PV Panel:

I decided to use just one large solar panel. This seems easier than mounting and wiring together several panels. The panel I selected the SW315 from Solar World. Its a 315 watt, 72 cell panel. The 72 cell design provides enough voltage (36 volts) to work with the KID charge controller as a single panel. I ordered the panel from the local Platt Electric — their price was competitive and if you pick it up at Platt there is no shipping charge. With a little discount they gave, it came to $368 — about $1.17 per peak watt. I have not mounted the panel yet. Thinking about mounting it as low as possible and aft of the Maxx Fan on the centerline of the roof.

Still thinking about the best way to bring the two wires from the PV panel into the van. I’m wondering if I can bring them through the backup camera housing?

I have not mounted the panel yet. Thinking about mounting it as low as possible and aft of the Maxx Fan on the centerline of the roof.

Still thinking about the best way to bring the two wires from the PV panel into the van. I’m wondering if I can bring them through the backup camera housing?

Update: August 2015: Solar panel mounted …

Update: Full details on the solar panel mounting and wiring here…

Update: March 2017 – new product to look at

Ran across this house battery charger. It will charge from the van alternator or solar (or both at same time). Its a full three stage charger that will charge the house battery optimally regardless of the alternator output voltage or solar panel voltage. It has charge profiles for all the common lead-acid batteries. The solar charger accepts only 12 volt PV panels, but it is an MPPT charger. It appears to be a new product, but definitely worth a look.

Wire:

For most of the DC and AC circuits, I used regular 14 gage Romex house wire. I used nearly all of one 250 coil. There are a couple runs that use 12 gage Romex due to higher demand and/or to reduce voltage drop. I’m aware that some sources recommend using stranded wire for greater vibration resistance, but the Romex is widely used in RV’s and does not appear to cause an problems. The outer plastic protective sheathing and its wide availability at low cost are pluses.Choosing wire type:

There is an ongoing (never ending:) discussion of solid vs stranded wire for RVs. In a nutshell, some believe that solid wire (eg Romex) is subject failure under high vibration conditions. On the other hand, its easy to work with, has the protective outer jacket, is inexpensive, is used in a lot of commercial RVs, and is built to a spec for consistent quality. I have not been able to find any accounts of actual failures of Romex due to vibration in actual RV service.

Stranded wire is said to be more vibration resistant, but is more susceptible to corrosion, and is more expensive.

If you decide to go with stranded wire, there are many choices. I thing this type of boat wire would be a good choice. It meets ABYC and Coast Guard standards, is tinned for better corrosion resistance, and has an outer jacket for better protection and easier routing. Its more expensive than Romex, but probably not a major expense in the context of total conversion cost. I would make sure that you get wire that is manufactured to a standard, and that the standard makes sense for use in RVs. Doing things like cutting the ends off cheap China extension cords to make RV wires seems like asking for trouble to me.

There were a few places where larger gage stranded THHN wire was used (e.g. between inverter and battery and between van and house battery). I got this all at Lowes where they will cut pieces to the length you want. A good way to go for picking wire gage is to use the BlueSea Circuit Wizard calculator. It uses the ABYC (American Boat and Yacht Council) boat wiring standards to size wires, which should be a good fit for RVs. It has inputs for voltage drop, multiple conductors bundled, load duration, and insulation temperature rating — be sure to examine all the inputs. The calculator is easy to use, and requires very little electrical knowledge to use successfully.Circuits

While the overall wiring diagram for the whole system gets a bit busy (and more than I am up to drawing), it really consists of a few simple functions that are largely independent of each other. This section goes through the details of each of the functions, which are:- House battery charging from the van alternator

- House battery charging from the solar panel

- Satisfying 12 volt DC loads (DC distribution panel)

- Satisfying 120 volt AC loads and Shore Power

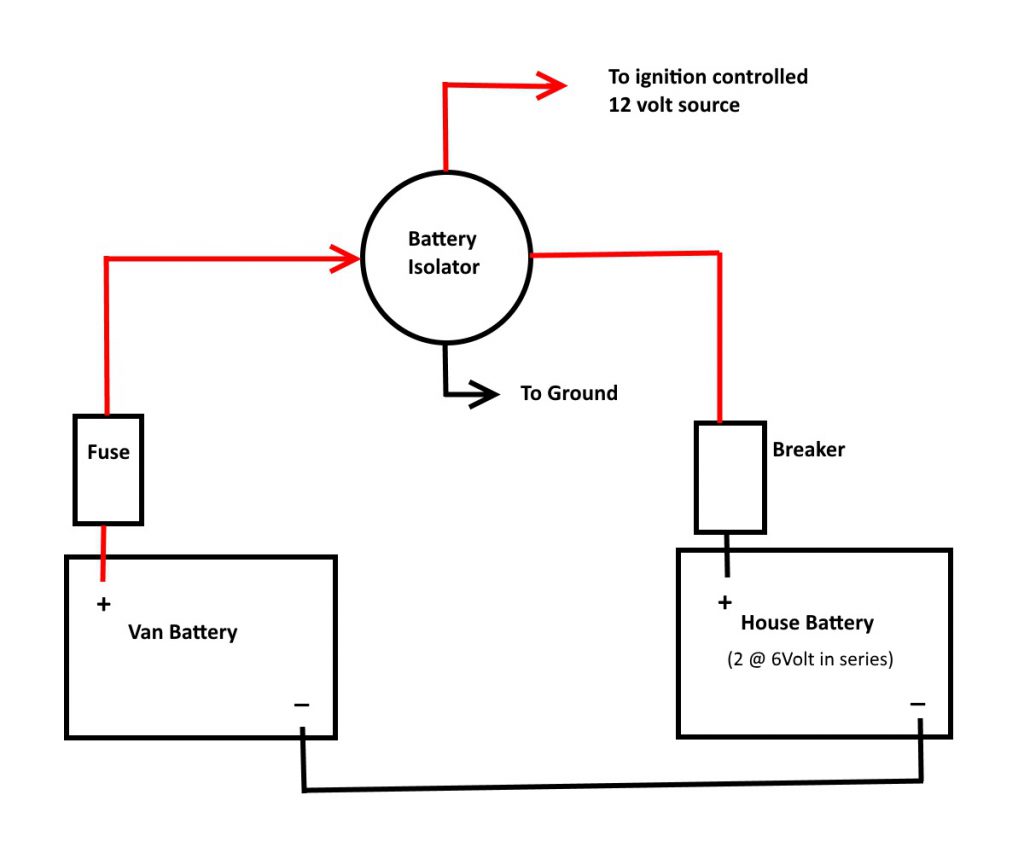

House Battery Charging from Van Alternator

This is the electrical subsystem responsible for charging the house battery from the van alternator when the van is running. When the van engine is running, the relay closes allowing the van battery/alternator to charge the house battery.

The battery isolator relay connects the van battery to the house battery only when the van ignition switch is on. This prevents house loads from discharging the the van battery and resulting in a vehicle that has a flat battery in the morning and won’t start.

The barratry isolator relay is turned on by connecting it to a 12 volt power source on the van that is only on when the ignition switch is on. I used power from the 12VDC outlet near the driver side back door as it is only powered when the ignition is on. I ran a 14 gage wire from the 12 VDC power socket to the battery isolator. The other relay terminal on the battery isolator is hooked to any handy ground. The isolator I used is a PAC-200 (see above) — the 200 amp rating is quite a bit more than is required.

The 50 amp DC circuit breaker protects the wire between the van and house batteries. The circuit breaker can also be manually switched off, so it acts as a disconnect when you want to be sure there is no connection between the van and house batteries. The breaker is sized to be a bit above the maximum recommended charging current for our batteries so that if the breaker trips we will know the battery is being charged at too high a rate. The maximum recommended charging rate flooded lead acid batteries is in the range of C/10 to C/5 (where C is the capacity of the battery in amp-hrs), so about 33 amps for our batteries.

The van alternator is the source of power for both charging the van battery and the house battery.

The wires between the house and van battery are 8 gage — this provides the 50 ampacity with less than 2% voltage drop for the about 10 ft run.

When the van engine is running, the relay closes allowing the van battery/alternator to charge the house battery.

The battery isolator relay connects the van battery to the house battery only when the van ignition switch is on. This prevents house loads from discharging the the van battery and resulting in a vehicle that has a flat battery in the morning and won’t start.

The barratry isolator relay is turned on by connecting it to a 12 volt power source on the van that is only on when the ignition switch is on. I used power from the 12VDC outlet near the driver side back door as it is only powered when the ignition is on. I ran a 14 gage wire from the 12 VDC power socket to the battery isolator. The other relay terminal on the battery isolator is hooked to any handy ground. The isolator I used is a PAC-200 (see above) — the 200 amp rating is quite a bit more than is required.

The 50 amp DC circuit breaker protects the wire between the van and house batteries. The circuit breaker can also be manually switched off, so it acts as a disconnect when you want to be sure there is no connection between the van and house batteries. The breaker is sized to be a bit above the maximum recommended charging current for our batteries so that if the breaker trips we will know the battery is being charged at too high a rate. The maximum recommended charging rate flooded lead acid batteries is in the range of C/10 to C/5 (where C is the capacity of the battery in amp-hrs), so about 33 amps for our batteries.

The van alternator is the source of power for both charging the van battery and the house battery.

The wires between the house and van battery are 8 gage — this provides the 50 ampacity with less than 2% voltage drop for the about 10 ft run.

Battery Charging from Solar Panel

This is the part of the electrical system that charges the house battery using a roof mounted PV panel.

Satisfying 12 Volt DC Loads

This is the part of the electrical system responsible to safely supplying power to the campers 12 volt load:

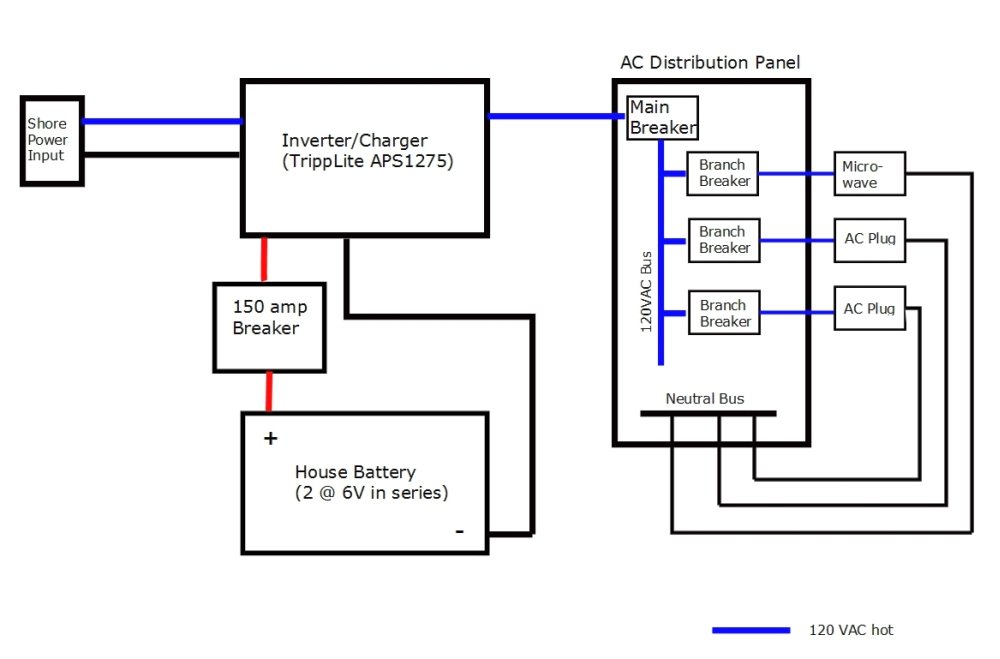

Satisfying 120 Volt AC Loads and Shore Power Battery Charging

This part of the electrical system is responsible for distributing power to the 120 VAC loads in the camper, and also manages whether the source of the AC power is shore power or the camper inverter. It also covers charging the house battery from shore power.

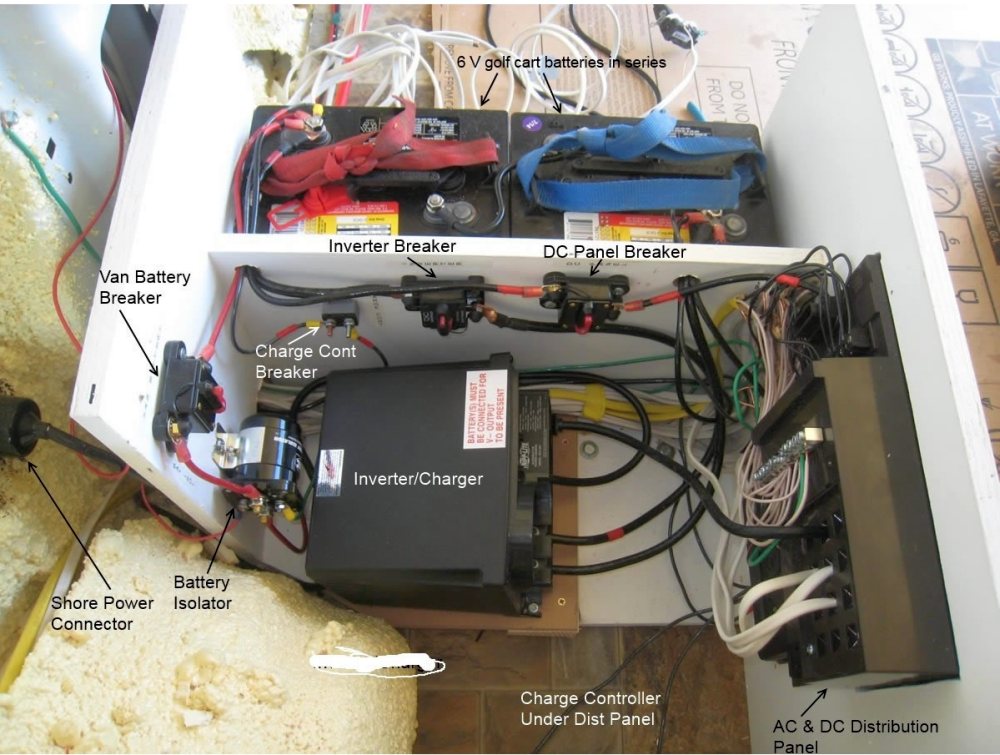

Installation

This section provides some pictures showing how I installed the components in our van. The batteries plus all the main components take up an about 2 by 2 ft space under the bed on the drivers side. The breakers can also be used as switches to disconnect each function.

The breaker marked “charge controller breaker” has since been changed to one that includes a manual reset so that it can be used to manually turn off the solar charging if needed.

The distribution panel on the right serves as both the DC and AC distribution panel — AC on forward end and DC on aft end.

The breakers can also be used as switches to disconnect each function.

The breaker marked “charge controller breaker” has since been changed to one that includes a manual reset so that it can be used to manually turn off the solar charging if needed.

The distribution panel on the right serves as both the DC and AC distribution panel — AC on forward end and DC on aft end.

Venting

The battery compartment is vented to the outside to prevent any buildup of Hydrogen in the compartment. The vent is 3/4 inch PVC that runs from the top of the battery compartment in a short run to the side of the van. A hole is drilled in the side of the van and a louvered aluminum cover keeps the water out. An about 7/8 inch hole was drilled through the front face of the battery compartment near the top (left picture). This was connected to the hole and vent cover in the van sidewall via a short 3/4 inch PVC pipe. The right picture shows the PVC vent pipe. Since the vent cover was larger than the 3/4 inch vent pipe, a PVC adapter fitting was used between the two. An inlet vent is also required, and this was placed in the inboard wall of the battery compartment about half way down. It is just a 3/4 hole drilled through the battery compartment wall into which a short piece of 1/2 inch PVC pipe is sealed in place.

Shore Power Cord

Its handy to have the things like the cord to hook up to shore power, the hose to fill with fresh water, and the hose to drain the grey water where they are easily accessible from the outside (where you use them). An outside compartment (say under the van) would be ideal for this, but I could not find a good spot. I decided to stow them on the back face of the bed platforms where they can be easily accessed from the outside via the back doors. The shore power cord (50 ft extension cord) and the fresh water fill hose are hung on the back of the passenger side bunk, and the grey water drain hose hangs on the back of the driver side bunk. This has worked out nicely.

The hangers are homemade out of short sections for 3 inch PVC pipe and screwed to the bed platform back wall.

Note Comments section at the end of this page — Tyler shows a way to put the shore power receptacle in the ProMaster bumper — so, no hole in the side of the van. He also shows a very simple way to do a single AC circuit for the van with one very simple and cheap fuse and switch arrangement that you can buy at Home Depot.

The shore power cord (50 ft extension cord) and the fresh water fill hose are hung on the back of the passenger side bunk, and the grey water drain hose hangs on the back of the driver side bunk. This has worked out nicely.

The hangers are homemade out of short sections for 3 inch PVC pipe and screwed to the bed platform back wall.

Note Comments section at the end of this page — Tyler shows a way to put the shore power receptacle in the ProMaster bumper — so, no hole in the side of the van. He also shows a very simple way to do a single AC circuit for the van with one very simple and cheap fuse and switch arrangement that you can buy at Home Depot.

Distribution Panel

This pictures shows the AC and DC distribution panel (top) and the solar charge controller (below). They are mounted on driver side bed enclosure facing the aisle between the two beds.

Switch Panel

I just recently added a small panel that adds on/off switches to the furnace and to the pump, and provides some extras for future use. It also provides 12 volt DC and USB charging outlets as well as a small volt meter to provide for easily monitoring the house battery voltage. The switch panel mounts next to the fuse panel on the vertical face of the driver side bed platform.

The two switches on the left are pump and furnace, and the remaining switches are spares for future use. We have always found it to be a good idea to turn the pump off when not in the RV, as any kind of leak or faucet left on will cause the pump to run and drain the tank and them damage the pump. The switch on the furnace allows you to completely turn the furnace off and still have other DC gadgets powered up.

The top row has a 12VDC outlet, then volt meter, then a dual USB outlet.

The blocks of wood on the top and bottom are to keep things from hitting the switches and accidentally tripping them.

I have not updated the wiring diagram to show this panel, but the switches are in the plus lead between the fuse and the the furnace or pump, and the switches should be rated to at least the same current as the fuses.

The switch panel mounts next to the fuse panel on the vertical face of the driver side bed platform.

The two switches on the left are pump and furnace, and the remaining switches are spares for future use. We have always found it to be a good idea to turn the pump off when not in the RV, as any kind of leak or faucet left on will cause the pump to run and drain the tank and them damage the pump. The switch on the furnace allows you to completely turn the furnace off and still have other DC gadgets powered up.

The top row has a 12VDC outlet, then volt meter, then a dual USB outlet.

The blocks of wood on the top and bottom are to keep things from hitting the switches and accidentally tripping them.

I have not updated the wiring diagram to show this panel, but the switches are in the plus lead between the fuse and the the furnace or pump, and the switches should be rated to at least the same current as the fuses.

Solar Charge Controller

The charge controller goes between the PV panel and the house battery and regulates and optimizes the charging of the battery. It also prevents the PV panel from overcharging the battery. The MidNite Solar KID charge controller is mounted in the bed enclosure just below the distribution panel. This means you have to get down on hands and knees to read the status, but it does keep the wire runs short and the electrical bay compact. If we decide to do upper cabinets (above the windows) in the van, I may move the charge controller to one of the upper cabinets for easier reading — I’d convert the hole for the current position into an air vent to ventilate the electronics area. There are several status screens that display various info about the solar charging — e.g. PV panel voltage, battery voltage, PV panel watts, …

Solar Panel Install

Full details on the solar panel mounting and wiring here…

Shore Power

Since our AC loads for the camper are small, I decided to just use a 15/20 amp shore power connection — this is just a regular 12 gage extension cord that plugs into an ordinary 120 VAC outlet. Most RV’s now use 30 amp or 50 amp shore power connections, but with our small AC loads we just don’t need that. This is the through wall connection we used: A bargain by RV part price standards at only $15.

These pictures below show installing the shore power receptacle.

A bargain by RV part price standards at only $15.

These pictures below show installing the shore power receptacle.

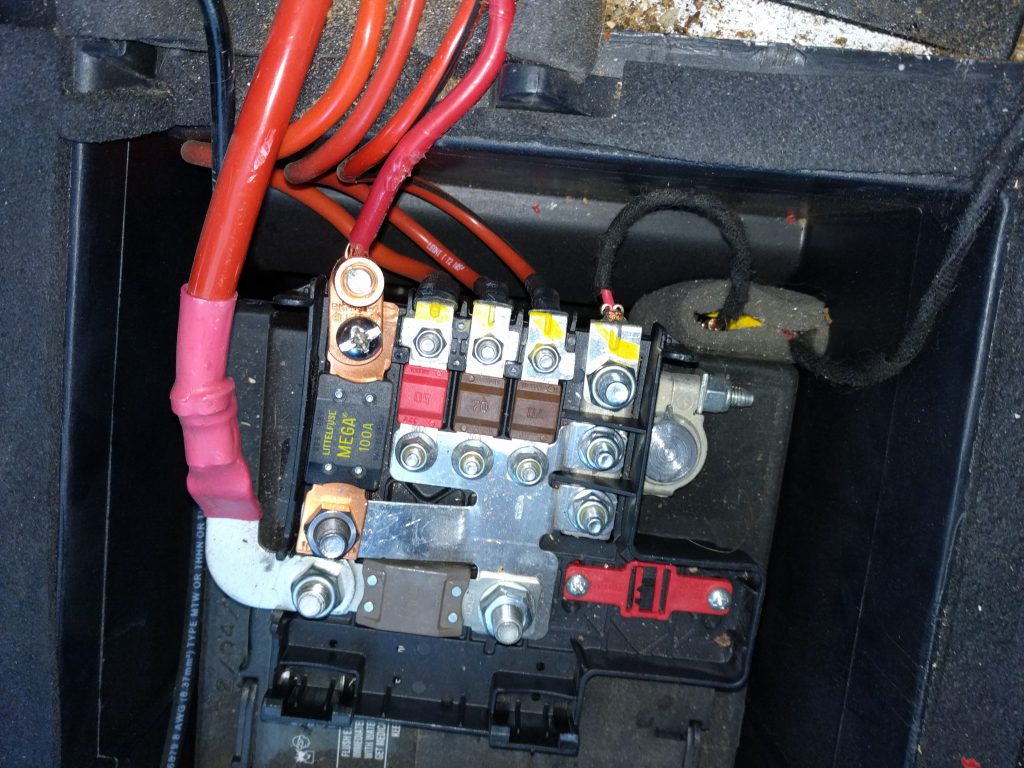

Connection to Van Battery

The connections to the van battery are shown below. I just used some unused connection points on the ProMaster battery terminal lug.

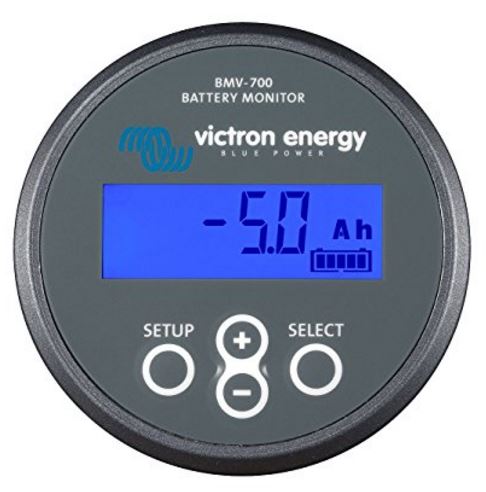

Adding A Battery Monitoring System

A Battery Monitoring System basically tells you with good accuracy how much juice is left in your battery at any time. It works by first sensing when the battery is at full charge, and then monitoring all the current going into and out of your battery and summing this up to let you know how much capacity is left. This is not a must item at all, but it does provide some useful information

Securing Heavy Components

The batteries weigh about 60 lbs each and the Inverter/Charger is also heavy. I was concerned about these breaking away in a crash and coming forward to injure passenger or driver. So, this end of the bed box is bolted down through the floor with five 3/8 inch steel bolts. The other end of this bed houses the propane bottle and is bolted through the floor with several more bolts. The bed boxes are made out of a premium quality MDO plywood with all joints glued and screwed.

Electrical Loads Estimate

I did a rough estimate of the power use while in camping mode, and estimated the battery size and PV panel size needed to support this load for a couple days. I have assumed an 80% battery discharge level in these estimates. I know that batteries will last longer if only discharged to 50%, or even less, but if you look at the Trojan estimate for number of charge/discharge cycles for an 80% discharge, its about 750 cycles. For an RV that only gets used maybe 30 days a year, 750 cycles is about 25 years, and I’m sure the battery will die of something else before 25 years. Maybe I’m missing something? The spreadsheet also includes a rough heat loss calculation to get the furnace size and the power drain for the furnace fan and electronics. This came out to about 3000 BTU/hr with 32F outside and 68F inside the van — this is for an insulated small van. If you have something that will view Excel Spreadsheets, download Excel Spreadsheet here… Otherwise, table below is copied out of the spreadsheet, but its hard to read because of the formatting.| Van Conversion — Electrical loads Estimate | |||||||||||||||

| These are loads for one 24 hr period. | |||||||||||||||

| Available Power From Battery | |||||||||||||||

| Battery size (amp-hr at 12V) | discharge depth | voltage | Energy avail (wh) | ||||||||||||

| 100 | 0.8 | 12 | 960 | Trojan SCS150 RV/Marine battery: 100 ah, 11.3 L X 6.7 W X 9.8 D | |||||||||||

| 200 | 0.8 |

12 |

1920 | This could be two of the Trojan 6V golf cart bats (or two Costco golf cart bats) in series | |||||||||||

| Might want to just leave space provisions for the 2nd battery. | |||||||||||||||

| Assumed below that things that are on all the time (CO detector, fridge) will run off the battery for 16 hours — that engine running or solar will take care of the rest) | |||||||||||||||

| Solar Panel: | |||||||||||||||

| Based on the stuff below, you would want the solar panels to put in about 500 wh over the day. | |||||||||||||||

| Electrical Loads: | |||||||||||||||

| Item | Usage | Time (min) | Wattage | Energy (wh) | |||||||||||

| Lights | three LED at 3.5 watts each? | 180 | 10 | 30.0 | |||||||||||

| water pump | 6 | 40 | 4.0 | ||||||||||||

| TV | 60 | 20 | 20.0 | ||||||||||||

| Hair Dryer | 4 | 500 | 33.3 | ||||||||||||

| Furnace fan | 210 | 22 | 77.0 | This is based on 14 hours per day when heating is needed at 25% load factor (see below) with 12K furnace, or 210 min | |||||||||||

| computer | 90 | 40 | 60.0 | ||||||||||||

| Fantastic fan | 30 | 21 | 10.5 | low 1.3 amp, hi 1.75 amp (note that this would be much higher for summer, but furnace would be lower) | |||||||||||

| CO detector | 960 | 1 | 16.0 | the 1 watt is just a guess — should find out | |||||||||||

| LP gas detector | 960 | 1 | 16.0 | the 1 watt is just a guess — should find out | |||||||||||

| Fridge | THIS ONE NEEDS REFINEMENT | 960 | 12 | 192.0 | This is roughly based on Jeff Yago’s article times about 3X — still seems kind of low. | ||||||||||

| 0.0 | |||||||||||||||

| Total | 458.8 | watt-hrs per day | |||||||||||||

| Optional added loads | |||||||||||||||

| microwave | minimal use if not on shore power | 0.12 | 700 | 84.0 | |||||||||||

| Notes: | |||||||||||||||

| Fridge: | |||||||||||||||

| * with this setup, and 80% discharge, the 12 V – 100 AH would be good for about 2 days, and the 2 6V 225 AH would be good for about 4 days (both probably less in the real world) | |||||||||||||||

| * JY says that good fridges use 2 to 3 ah/day per cf — conservatively use 4 ah/day-cf. | |||||||||||||||

| A 1.7 cf fridge then uses (4ah/day-cf)(1.7 cf) = 6.8 ah/day, or (6.8 ah/day)(12 volts) = 82 wh/day, with an average draw of 3.5 watts (seems low) | |||||||||||||||

| Dometic says 40 watts, but this would be 365 KWH per year, which seems high for a tiny RV fridge. | |||||||||||||||

| Need a better source for power used by the Danfoss compressor fridges. | |||||||||||||||

| * At 0 F outside temperature, the furnace would be on twice as much and furnace watt hours would be 150 ish. | |||||||||||||||

| http://www.rvfurnace.info/ | |||||||||||||||

| * In summer, more fan operation might add as much as 200 or so wh, but furnace would drop to 0 (-62 wh) | |||||||||||||||

| * adding a microwave even if operated on battery would not be too awful as long as time of use is limited. | |||||||||||||||

| Van heat loss : | |||||||||||||||

| Item | area | R value | Tavg outside | Tin | Heat loss (BTU/hr) | ||||||||||

| walls | 210 | 6 | 32 | 68 | 1260 | ||||||||||

| Floor | 78 | 9 | 32 | 68 | 312 | ||||||||||

| ceiling | 72 | 6 | 32 | 68 | 432 | ||||||||||

| windows single | 30 | 1.5 | 32 | 68 | 720 | ||||||||||

| windows double | 18 | 3 | 32 | 68 | 216 | ||||||||||

| infiltration | 468 | 32 | 68 | 82 | at 3.0 ach | ||||||||||

| Total Heat Loss | 3022 | BTU/hr | |||||||||||||

| So, a 12K BTU/hr furnace would be running (3022/12000= 25% of the time) | |||||||||||||||

| Propane burn per day would be (3000 BTU/hr)(24 hrs)/(92000 BTU/gal) (0.8 efic) = 0.97 gal/day | |||||||||||||||

Solar Panel Charging:

Using PVWatts as a rough way to estimate output…For a 315 watt panel mounted horizontally in Billings MT, the average output per day is:This is with average weather for Billings — you can, of course, have full overcast days with very little production. Our estimated use per day is about 400 watt-hrs, so for most of the year, on average, a 315 watt panel would easily meet our daily needs even with the horizontal tilt. For the deep winter, the panel only meets about 75% of our daily usage, but if it could be tilted, it would meet our daily needs with a bit of margin. The above are with a PVWatts service factor of 0.77 — the real world one may be a bit less than this with the battery charge/discharge inefficiency included. Note that PVWatts has a bug that results in inaccurate output with arrays smaller than 1 KWH, so you have to put in a larger array, and then just scale the output numbers down.1575 watt-hrs per day in July 440 watt-hrs per day in October 300 watt-hrs per day in December With tilt equal to latitude (46 deg), the July number goes to 1450 wh/day and the Dec output goes to 800 wh/day.

How Has It All Worked Out?

After three trips in the camper van, I’d say the electrical system is doing fine. It runs all of our loads fine, including the two main loads: the fridge (about 42 amp-hrs per day) and the furnace (about 20 amp-hrs per day). There have been no malfunctions, and the only maintenance was to add water to the battery once. The solar panel has only been in place for the last trip, and its performance has been fine. While I have not carefully analyzed this, I think that for Spring, Summer, and Fall trips the solar panel will be able to provide all of the juice needed on sunny or part sunny days. Dead of winter trips are harder because the sun is lower and there are more cloudy days. I’ll try to log some actual data on how the solar charger performs with no charging from the van alternator on the next trip. At some point, I may add a TriMetric system to keep better track of the battery pack state of charge, but this is probably more out of satisfying curiosity than actual need. 2019 Update: The van now has 5 years and 70K+ miles on it and the electrical system has held up well. No significant problems or changes 🙂Weights, Costs, Labor

I did not keep track of the time spent installing the electrical system as it was spread out over a month. It was probably roughly the equivalent of 3 full days. Gary September 18, 2014

Item Description Weight (lb) Cost ($) House Battery 2 @ 6 volt, 200 AH golf cart batteries (Costco) 120 $180 Inverter/Charger Triplite APS 1250 Inverter/Charger 23.2 $406 Battery Isolator PAC-200 Battery Isolator 200 amp 2? $46 MPPT Charge Controller Midnite Solar KID Charge Controller 6 $280 AC/DC Distribution Panel PD5000 AC/DC Power Control Panel 2? $58 PV Panel SolarWorld SW315 PV panel 49.6 $368 Circuit breakers 2? 64 Wire #14 and #12 Romex 220 ft #14 Romex, 25 ft #12 Romex 14.6 $40 Other wire #2, #8, #6 short lengths 15? $30? Terminals 1? $20? Shore Power receptacle 1 $15 Inside lights, … TBD TBD Total 236 $1507

I am impressed of your article. I want to buy solar panels too

Wow!! Amazing blog. Solar panel installation is important for saving money and the environment. Solar panels are an excellent way to save money on electricity bills because they generate the electricity you use for your home.

Hi David,

I’m a strong supporter of solar for both homes and vans, but for vans there vans there is a caveat on the environmental front.

Solar panels on a van definitely charge the house battery and reduce the carbon emissions that would go with charging the batteries from the van alternator. But, the roof mounted panels also cause aero drag and this makes the van consume more gas when driving. So, ideally, the PV panels are installed in such a way that the aero drag increase for the van is small to none. This could be the flexible PV panels mounted right to the roof surface, or a conventional panel mounted in as low drag a configuration as possible.

In general, mounting the PV panels low to the roof and as far back as possible decreases drag. Some testing I’ve done also indicates that an elliptical nose fairing on the front edge of the panel reduces drag.

Search around on this site for “drag” to see some test results.

Gary

Gary

Do you remember what size/ particular bolts you used were to connect the fuse on the positive side of the van battery in the slot thats available? I noticed its just empty slot when going to install.

Hi Andrew,

I don’t remember right off hand – I’ll see if I can take a look today.

Gary

Thanks! No rush. Appreciate the help.

Hi Andrew,

All of the bolts in the lower left corner of the picture of the wires coming into the van battery are 8 mm. I don’t think the length is critical – maybe about 3/4 inch?

Gary

Thanks so much! Appreciate you taking the time to check.

Love your site and clear, descriptive explanations! Read all your comments in the forum – always the common sense answer.

Don’t understand the daily use you talk about above. If your fridge uses 42 AH, does this not equal 500 WH on its own? You talk about daily use of about 400 WH, easily covered by the 315W solar panel. I’m new to the electrics, and trying to figure out my needs. About the same uses as you, fridge, fan, shurflo pump, led lights, usb chargers, small monitors, maybe a small AC coffee maker. (650 watts). 330 watts of solar and 2 110amp batteries.

Hi,

Good pickup – thanks.

I wrote the stuff above before doing the actual test on fridge energy use. I used an estimate on fridge watt-hrs from another source and it turned out to be optimistic.

I’ll rewrite the above section based on actual experience over the last 5 years.

Just looking over the table of loads after 5 years of usage, I think the fridge is the only one that is way off, but in hindsight some of the other durations for some of the loads seem a bit higher than actual.

Gary

I love your design and will be copying it pretty much the same for my van. I have a few differences if I can ask? First, I want to use an 120v rc fridge plus add 5k-7.5k btu window unit in rear door (not window). Will use hand pump with (spring)water jug no pump, no hair dryer no furnace. My question is, and I think I know the answer, do you see a problem with 120v fridge and A/C unit on same system as yours and have fridge run while driving? Thanks

Hi Edward,

The 120VAC fridges work in RV’s and a few people use them. But, most find that in the end its worth paying up for the 12 volt RV models even though the price premium hurts. The 12 volt models are more efficient and they don’t require running the inverter all the time (which eats some power).

The 120VAC fridges may require a pure sine wave inverter — not sure.

The 6K BTU AC would be by far your largest load. Probably about 500 watts or about 46 amps out of your 12 volt battery all the time its running. You would not be able to run it very long off the two golf cart battery setup — a couple hours would discharge down to 50%.

You mention driving while running the AC — this would help, but I think its unlikely that you would get enough charging from the van alternator to keep up with continuous AC use. About the best I’ve seen on sustained charging is 30 amps.

Most of the people who try to use an AC in a van on batteries have huge battery packs (eg 600 amp-hrs) and still can’t run the AC all the time. Its a tough problem. Most people end up resorting to shore power or a generator.

For the kinds of loads you are talking about, you would definitely want to go with a better inverter/charger than I did, and one that is pure sine wave — especially since the price premium for these has dropped.

Gary

I would just run fridge while driving to camp then connect to shore power,,,no a/c whiling driving just fridge. Thx

I’m going to just use unit (inverter) for fridge when driving to shore power, maybe phone charger etc no air conditioning while driving. I will use shore power for all other appliances. Question? I have 30 amp shore power chord and wish to connect to 30 amp service while at camp sites but use 15 amp adapter while home to charge batteries etc,,,,,I assume just use 30 amp out instead of 20 amp which you used???? will it wire the same just different plug for 30 vs 20 amp? Correct? thx

Hi,

Yes — I think that should be fine.

Gary

Gary,

After doing my van build (following your advice), I cannot help but notice when see products that might be better for the next time. I’m interested in this battery isolator. It’s the voltage sensing kind. https://www.amazon.com/dp/B0058SGDFK/

What do you think?

Hey Dennis,

I think its fine — not sure its better.

There has been a lot of discussion of the doctor on the PM forum — some people think its the cat’s meow, others not so much.

You get the button that allows you to parallel the batteries for a jump start when van battery is down, but you can do the same thing with a little jumper wire and a regular isolator.

I think it just comes down to whether you think the extra functions are worth the extra complications and cost. I think I would probably just go with a regular isolator if I was doing it again — kind of a personal taste thing I think.

Gary

I’m doing a cargo trailer conversion and am curious how you wired the Inverter/Charger to your shore power as well as to the AC breaker. This wasn’t clear to me and I didn’t want to make any assumptions. Thanks.

Hi Roman,

My inverter charger on its 120 VAC output had a cord terminated with a regular female 120 VAC plug. I cut the plug off and wired 1) the hot wire to the main breaker in the AC distribution panel, 2) the ground (green) wire to the ground bus in AC panel, and 3) the neutral (white) wire to the AC panel neutral bus. The inverter/charger automatically connects this 120VAC out wire to either shore power (if plugged in) or to the inverter (if enabled). It also takes care of bonding the neutral wire to the ground at the inverter charger and unbonding it if you are on shore power.

The shore power connection basically just a cord with a male plug that comes out of the inverter/charger and plugs into a 120 VAC shore plug at the campground power pedestal.

The line on mine is broken by the outside socket installed in the van skin so I don’t have to run an extension cord through a door or window.

There is also a ground wire from the inverter/charger that I connected to the ground bus in the AC panel.

I don’t actually recommend the model of inverter charger that I got as there are better cheaper ones out there now — including ones that have pure sinewave inverters.

You always want to follow the hookup instructions in the manual.

Gary

Which newer inverter/chargers do you like instead of the Aps1250? The 1250 looks pretty good and tough with auto mode etc,,,which others do you perfer?

Hi Ed,

The APS 1250 has been reliable and I think TripLite makes good stuff. But, its not a true sinewave inverter, and some things won’t run on it.

I have been looking at inverter/chargers lately, and one that I like is this one:

https://www.donrowe.com/samlex-evo-1212f-pure-sine-inverter-charger-p/evo-1212f.htm

Gary

Great, I have a APS 1250 and next time I will look into true sinewave.

I want to use (1)maybe (2) AMG 12v 100ah batteries because no spill, less venting, plus I can’t find a 6v under $200 in this town. I understand the 6v is a better system but don’t like “flooded” inside my van. Your thoughts?

Hi Ed,

It sounds like you understand the tradeoffs between AGM and flooded batteries. Most people do choose AGM’s. Its just a case of looking at the pros and cons and picking the one you like the best.

If you do plan to use the inverter to run largish AC loads, I would go for the two 100 amp-hr batteries rather than just one — the inverter draws a lot of current with larger AC loads and would likely be beyond the peak current a 100 amp-hr battery can provide.

The 200 amp-hrs also gives you more reserve. If you plan to use an electric fridge, this alone will use about 40 amp-hrs a day, and you should never take the battery below 20% state of charge.

Gary

Question: Cannot see any detail pics on your build for this: For the electrical outlets, whether 120VAC or 12VDC, are you using standard 2×4 boxes, or just running the wires bare to the back of outlet plates, with them secured thru the paneling? Or are they mounted in the steel cutouts in the PM walls? (Have to sort these things out BEFORE insulating and paneling, right??)

Hi Dave,

All of my 120 VAC outlets are in standard residential plastic outlet boxes — wired just the way they would be in a house.

I think that all of my 120 VAC outlets are in the galley cabinet and in the bed pedestals, so I did not have to figure out how to mount 120 VAC outlets to the van wall or paneling.

We have actually found that we don’t use the 120 VAC outlets very much — most of our stuff is 12 volt DC. But, still need a couple 120 VAC outlets.

Gary

I have the same inverter/charger and distribution panel as you, and I too cut off the plug end of the input cable (7B) and wired it to my shore power elec. entrance. I was planning on using the left over plug end to plug into the inverter/charger’s output receptacle, and to then route that cable end to my distribution panel’s AC bus bars.

However the wires in that cord are only 14 AWG, and would be overloaded before the 30 amp main disconnect breaker in the AC panel would trip. Is this not a concern?

Hi Jim,

Sorry about the slow response – we have been without internet up north.

I did the same thing and used the cut cord for both connections.

For shore power from van to power pedestal, I use a regular #14 extension cord and I plug into the regular 120 VAC outlet on the power pedestal, so its protected by the 20 amp breaker in the power pedestal. The nice thing about using the #14 extn cord is that a 50 footer takes up little space vs what a 50 ft #10 extn would.

The TripLite box itself may also provide protection on its outlet side — certainly when its on inverter, but maybe also when on shore power.

I do think that it would be good to either switch out the main breaker from 30 amp that it comes with to a 20 amp, or get a short #12 extn cord an cut the female end off and use it the way you were going to use the cut off TripLite cord.

I think I will pick up a 20 amp breaker for mine next time I’m down at the hardware — I know I thought about doing that when I first installed, but it fell out of my head.

Short story about current capacity of a #14 wire: I was changing out the circuit breaker box on the last house we had, and was finishing the wiring with the box hot to get the power back on sooner for the family. I had a #14 green insulated ground wire tied up to the ceiling above the box waiting to be hooked up. The wire got detached an swung down an its tip hit the main bus bar of the breaker box – big flash and then darkness. In about the zero time, the #14 wire blew the 200 amp main breaker. The plastic insulation on the ground wire was not even damaged. Obviously not a way to size wire, but interesting how much capacity a smallish wire has for hard shorts.

Gary

Here is a photo of how I routed the wires from the van battery to the house battery.

Hi, Great build! Can you tell me which wire is the “hot” wire that you connected to for battery isolator power? I have a Promaster 2018 and there is a black and a yellow wire leading fro the DC power outlet at the rear of the vehicle. Thanks! Any photos will be helpful!

Hi Patrick,

Unfortunately, did not take any pictures, and that area is kind of hard to get to now.

You can identify the + wire with a multimeter easily. If you don’t have one yet, the $5 ones from (for example) Harbor Freight work fine and are useful for lots of things.

Gary

Gary, You set the switch on the Inverter to Auto/Remote, plug in the ethernet cable to the Inverter and the Remote, and then the Remote Control switch will allow you to select either Auto or Charge Only. It doesn’t have the option to turn it off, but that makes sense.

Thanks Dennis

I thought I’d try again and see if it was upright.

Hi Dennis,

Vey nice.

Are the switches that are on the front of the inverter available from the remote? That is, can you switch between charge only and auto from the remote.

Gary

My location for the Tripp Lite inverter made it not easy to see, so I purchased a remote for the inverter on eBay.

I just finished the outside vent for the battery compartment. I used a common rv battery vent: https://www.ebay.com/itm/162915707716

The second vent hole you added is open to the inside of the van. Wouldn’t it be better to drill a hole in the bottom for fresh air intake?

Hi Dennis,

Nice looking vent.

I was reluctant to drill any more holes through the outer wall, so went with the inside inlet. The flow volume is very low, and it seems like there should be plenty of air inside the van to supply it.

Not even sure that there is any flow into the inlet vent in that the H generated in the battery cells is new gas, so it can rise out of the outlet vent without the need to pull in new air?

As mentioned above, I’m a bit skeptical of the whole venting thing, but decided to go with doing it by the rules.

Gary

Gary,

Are these the type of circuit breakers you used? If so, how many amps do you recommend?

https://www.amazon.com/60Amp-Circuit-Breaker-Marine-Stereo/dp/B076GVZYHX

Hi Dennis,

Its the same design and look, but I think the brand is different. The ones I used (I think) are just a generic China import.

I had one go out just a few days ago, and replaced it with a similar looking one that is made by LittleFuse — it might be worth looking for these as LittleFuse is a well know brand.

Sizes depend on what you are fusing.

Gary

Here’s a picture of the tabs that need to be bent in order to make proper contact with the breakers in the AC section of the distribution box. The tabs need to be bent to the left. That seems impossible, because they’re flat in that direction, but it works as apparently the hidden rod/connector in that they are all part of does bend. I was afraid the thin plastic box would break, but it didn’t.

It’s critical that the breakers make good contact with the tabs, otherwise arcing can occur. In my case, they were very loose, and contact was interrupted.

AH, Perfect! I haven’t tried it yet, but will this week. Thanks again!

Thanks Paul

Gary

I’ll take it apart tomorrow and take a picture.

Thanks a lot, Paul. Much appreciated :o)

I took Rick’s advice and bent the tabs. I was a bit reluctant, as I was afraid I might break the plastic housing that holds the rod and tabs, but it worked. And it made all the difference; now the breakers have good contact and are not so loose and wobbly.

Thanks Rick!

Can you possibly post a photo of just where to bend? I have the same problem – thought it was just how these things fit. Thanks to you and Rick for bringing this up and suggesting a solution.

Paul or Rick — if you have a photo, you should be able to post it using the “browse” button to select a file on your computer, which will be added to your comment reply.

Gary

Gary, What exact brand of breakers did you use in your box? I have the same PD5000 box and used Square D Homeline, one of the ones recommended, but they’re all really loose and wobbly, and now I’m having problems with them actually losing contact and turning off power.

I noticed how feebly the breakers fir in the first place, and frankly, I’m pretty disappointed with that aspect of the unit. This would not happen in a residential box.

Are yours in there securely?

I had the same problem using the same breaker and distribution panel. I found the problem with the panel, not the breaker. The post that the breaker clamps onto needed to be adjusted by bending it with a pair of pliers. I found the breaker was barely clamping onto the metal post. It was a simple fix. I hope that helps you.

Hi Paul,

The breakers I have are square D Type TIPO HOM

The 15s are DP4075 and the 30 is a PA5283.

I’ve not had any problems with them heating up or not making a connection, but now that you mention it, they do seem to fit kind of loosely.

Maybe try Rick’s suggestion — I think that I will.

Thanks Rick.

I’ll send an email into the manufacturer and see what they have to say.

Gary

Van conversion is slowly chugging along. As with all my projects, it takes longer and costs more than I thought. lol Where did you get the battery box vent cap that goes on the outside of the van. tried several different searches, so I thought i would ask you. Hope you remember!

Regards

Georg

Hi Georg,

It was a vent I bought at a local hardware store. Its alum and I think its intended use might be for home soffit venting.

Seems to work fine and not corroding.

I think I just installed it with silicone caulk.

Gary

Gary,

Thanks for your input on the investor/charger. I’m also looking for a solar panel equipment.

Here is a panel that is close to yours: https://a1solarstore.com/solarworld-plus-300w-solar-panel.html?gclid=EAIaIQobChMIscSh4pO-3AIViDaBCh106A6oEAkYASABEgIcyvD_BwE

Here is a controller:

https://www.amazon.com/Victron-SmartSolar-Charge-Controller-Bluetooth/dp/B075NPQHQK?th=1

What do you think about both of these?

Hi Dennis,

They look like good choices to me.

SolarWorld has a good reputation and they specifically mention hail and sand resistance, which might be more of an issue for a PV panel moving along the highway at 70 mph 🙂

The price per watt is good, but you also always want to consider shipping cost for PV panels. I ended up getting mine from our local Platt Electrical — the price per watt was a little higher, but no shipping charge.

I like the charge controller and its nice to see controllers coming out that handle the larger pv panels and don’t cost $400 (like the current price on our Kid controller). I have a Victron battery monitor and think it is well engineered.

One thing I’m not quite clear on is the 20 amp spec and whether it applies to the maximum charge current going into the battery. If the charge current going into the battery is limited to 20 amps, then you will be right at the limit with your 300 watt panel (eg 300 watts/13 volts = 23 amps). This is not going to happen very often, but on a full sun cool day you could get there. Question is, what happens when the charge current goes over 20 amps? Does it shut down, or does it just clip the charge current at 20 amps? Clipping the charge current at 20 amps (to me) would not be a problem as you are not going to get the full 300 watts out of the panel very often, but if it shuts down, that could be an inconvenience. I guess one option would be to go for the 30 amp model.

The other thing to think about is the Bluetooth interface. The up side appears to be that you get much more data on whats going on, the (maybe) downside is that its nice to have an actual panel on the controller you can take a quick look at any time without having to have your phone and having to deal with any sort of pairing or communications issues. I’d probably opt for the Bluetooth if I had the option.

If you get the charge controller, please let us know how it works out.

Gary

Gary,

I decided to go with the same refrigerator you used. Thanks for your great research! Now I’m working on electrical. This unit is larger than your Tripplite Invertor/Charger, but do you think it would be a good replacement? It’s about the same price.

https://www.hodgesmarine.com/Xantrex-Freedom-Hf-1800-Inverter-Charger-p/xan806-1840.htm

Hi Dennis,

Xantrex is a good brand and this looks like a good unit. Even thou its produces more power than the TrippLite, it looks a bit more compact, which is good. I like the display panel better than my TrippLite in that it shows more and is better oriented. Looks like a good unit to me.

About the only doubt I would have is whether you want to go for a pure sine wave one or not. As I mention on the electrical page, they have come down in price, so you don’t save as much as you used to by going for a modified sine wave. That said, there has only been one AC load that I’ve tried that did not want to work right on my modified sine inverter and it was not really something I needed.

The fact that they are pushing it for EMS service probably indicates they have a lot of confidence in the output wave shape.

If you get it, please let us know how it works out.

Gary

My electrical system is very much patterned after yours (thanks!) except that I have a 2000W Xantrex inverter. I tried running a microwave that was left behind by a tenant because it has a manual timer, so no parasitic drain. It draws 1000W. After about 2-3 minutes, the Xantrex shuts off. I watched voltage very carefully: it started at about 12.6 or so, and then drops fairly steadily until the Xantrex shuts off right at about 11.5-11.4 volts. The default low voltage cuttoff is supposed to be 10.5 V and I checked that it is on that setting.

I called Xantrex and they basically said there’s something wrong because the voltage dropped so quickly (from 12.6 to 11.5 in about 3 minutes) and that’s why it’s shutting off well before the 10.5 V low voltage cutoff.

I’m very inexperienced with 12V battery systems. I have new batteries just like yours, and my Victron shows them to be 100% when starting, and at about 96-97% or so after the 3 minutes or so. My battery cables are oversize and very short.

Do you have any suggestions/thoughts? Does that voltage drop seem excessive to you? I’d like to know that I can run this MW for at least 5-8 minutes or so.

Hi Paul,

Seems like your setup should work.

Maybe check that all the contacts are corrosion free and well tightened, but I suspect you have already done that.

If you have a Kill-A-Watt, you could plug the microwave into a regular house outlet and see what it actually draws. Microwaves are rated on output, so if its a 1000 watt output microwave, its probably drawing more like 1250 watts, which should still be OK.

They do make small 700 watt microwaves which actually draw like 900 watts — if you have access to one, you might try that.

If the batteries you got have tech support line, you might call them an ask if the batteries can supply about (1250 watts) / (12 volts) (0.9 ) = 117 amps.

amps plus more on startup. Where 0.9 is the inverter efficiency.

If they don’t have a support line, maybe see if max current is listed on the Trojan site for their T105 golf cart battery — Trojans are good, so brand X may not do quite as well.

I don’t understand the Xantrex statement that the inverter has a cutoff voltage of 10.5 volts, but sometimes it shuts off at 11.5 volts?

If the Xantrex is not a pure sine wave, I guess there is the possibility that the microwave does not like the power quality from the inverter, but seems like it would make noises and not work well rather than causing the inverter to shut down?

You might try seeing if running the engine while using the microwave. If that fixes the problem — I guess that would lead to the conclusion that batteries are not sufficient (or may microwave is drawing more power than it should).

It seems like people do successfully run a small microwave with two golf cart batteries, so I think something must be wrong.

Please let us know what you work out for a solution.

Gary

All my contacts are shiny new and very tight. It’s a 600W output microwave that draws just under 1000watts (confirmed with my KillaWatt). The Xantrex is pure sine wave; that’s why I got it.

I plugged in a 600w space heater; it ran about twice as long 5-6 minutes, but when the voltage dropped to about 11.5, the Xantrex shut off.

I need to find out how quickly voltage should drop, and whether 11.4-11.5 is low or not. But something is clearly not right; I assumed that running the microwave for 3-6 minutes was not going to be an issue.

Thanks.

Hi,

Battery capacity wise, the 1000 watt microwave should draw about 1000 / 12*0.9 = 92 amps. So, 6 minuites (1/10th hour) is only about 92 amps * 0.1 hr = 9 amp-hrs — so, not much of anything to a 200 amp-hr pair of golf cart batteries. I’d think you should be able to run this load for an hour without a problem.

I’ll try running a space heater off my battery and inverter tomorrow and note how fast the voltage drops, but that seems like a lot of drop for just a few minutes. Will let you know.

Gary

Hi,

I ran an 800 watt space heater off my inverter for 12 minutes with following .

Time in minutes from space heater turn on.

Voltage and current read on Victron battery monitor.

Space heater watts read on a Kill-A-Watt meter.

So, each line below gives time in minutes since space heater turned on, then battery voltage, then space heater watts, then (for some times) the current being drawn from house battery.

Time Voltage watts current

0 12.98 0 0 (no load)

0+ 12.17 800 82.7 (heater on)

1 12.10 763 81.8

2 12.06 760

3 12.04 770

4 11.97 780

5 11.93 758

6 11.87 762

7 11.82 780

8 11.79 778

9 11.78 774

10 11.77 804

11 11.75 780

12 11.74 778

13 turn on engine

13 12.52

Initially, the battery voltage drops fairly quickly when space heater load is applied, but toward the end of test, the voltage drop rate per minute slows down — I think it would have continued running for quite a while without a problem.

I guess a tentative conclusion is that your two golf cart batteries should be able to run your microwave OK. Seems like most likely problem is bad batteries, or bad inverter. Checking with your PM engine running might help to shed some light?

Interesting thing is that about a minute after I turned the engine on, the breaker in the charging line from the van battery (alternator) to the house battery popped. Its a 60 amp breaker, and has never popped before. So, I guess the alternator was trying to supply some of the current for the space heater and went beyond the 60 amp breaker capability. So, if you plan to run the engine during times when microwave is on, plan the line and breaker from the alternator/van battery accordingly.

Please let us know what the problem turns out to be.

Gary

Thanks for that. It’s about what I would have expected. Something is clearly off.

I bought the interstates like yours from Costco early this spring. I wanted to dry run the electric system so I set up the solar panel and Kidd solar charger in the back yard, and I called Interstate to get the charging specs on those batteries, and set up the Kidd with them. And they sat there for months at full charge. I also hooked up the inverter too and made a few short test runs, but not more than very brief ones.

I need to figure out whether it’s the batteries or the inverter. Dang; I sure hate to take it all apart now that’s it’s all hooked up and bolted down in the van.

I haven’t even tried to run the engine yet with a load on it. The solar panel and charger must be contributing a bit too while the load is on.

The charge voltages I got from Interstate were: 13.8 absorb, 13.5 float, 13.5 equalize.

When there’s no load, my battery voltage is in the 13.6-13.7 range. Seems a bit high, but that’s what they gave me. But the moment a load is on, it drops to about 12.7 or so.

One more thought: voltage drop due to resistance. I used 2/0 welding type cable, which is safely above the Xantrex recommendations, and the runs are extremely short, as the setup is similar to yours. Big solid copper lugs. All very tight. But I did wonder about the 250A main breaker, a cheap Chinese unit. It seemed rather light weight to handle that much juice, including its smallish lugs. I wonder if it’s possibly a source of resistance?

I guess you could short around the breaker for a short time with a heavy wire to see if the breaker is the problem. Or, maybe just replace the CB if it seems suspect?

Gary

Gary. Just as I thought: that cheap breaker was the problem. Bypassed it, and with the 1000W MW on, voltage dropped quickly to 11.7-11.6, but then stayed there rock steady.

What kind of main DC breaker did you use?

Also, just to confirm what you told another commenter regarding that AC/DC panel: the AC side should not have a link to chassis ground, right? There were no instructions with that panel, so I wasn’t sure, but I had my doubts.

Hi Paul,

Nice that it turned out to be a cheap part rather than the batteries or inverter.

I just used a generic 12 volt breaker from Amazon, but if you want a higher quality breaker, I’d have a look at what BlueSea or maybe Bussman has — both good brands.

The way I understand it is that the on the AC side, the neutral and ground should be tied together at only one point. When on shore power, this point is back at the power pedestal the campground provides, but when you are on the inverter the tie point should be at the inverter. So, the ground/neutral tie point changes between shore and inverter power. Most of the inverter/chargers will handle this automatically when you go from one to the other. If you are using a standalone inverter, then this is something to look into — I think you will have to switch the ground neutral tie point with wiring and a switch you provide, but I’m not sure.

The reason for doing it this way is a safety issue. With certain kinds of failures, you can get a hot chassis situation if the ground to neutral tie point is not in the right place and only in one place.

Gary

Hi Gary,

I’ve finally gotten down to putting in the electrical system in my van conversion, and have some questions about the PD-5000 DP — I have the same one, but I’m really confused about a couple of things, so I apologize in advance for being so dense.

First, on the DC side: where does the cable from the house battery connect to the panel? I see the two bus bars on the rear, one directly behind the DC fuse panel (assuming these are the positive connections), and the one behind the AC breakers (this is the DC negative bus, correct?). The only other place I see that is a candidate is the small protrusion, also behind the DC fuse panel, that has two screws in it, but I can’t figure out what type of connector to use, if that is indeed the DC input. And why are there 2 screws there? I thought the DC negative bus should be connected to the battery negative terminal and/or chassis ground – is the second connector supposed to be connected to the battery negative?

OK, now for the AC side: I see a neutral bus and a ground bus; again, I’m assuming the ground bus gets connected to a chassis ground (although I notice you said you’d forgotten to do that until much later), but what does the neutral bus get connected to? Should that be connected to the inverter [AIMS 2000W inverter/converter] negative terminal?

Thanks again for your great website and all the great discussion on this site!

Lorraine

Hi Lorraine,

The system seems to have eaten my earlier answer, so will try again.

The place you see as a candidate is the right place to hook up to the house battery. Just use one of the screws and leave the other disconnected. Definitely do not hook the 2nd screw up to the neg terminal of the house battery — this would cause lots of fireworks.

You are also right on the two bus bars on the back of the DC panel — the one that is insulated between screws is for the positive wires going to your DC loads (each screw is connected to its own fuse). The non-insulated bus is for the negative return wires from your DC loads.

For the AC side…

On my setup, there is a standard AC three wire cord from the inverter output to the PD panel – black (hot), white (neutral), and green (ground) wires. The black is connected to the main breaker of the PD panel. The white goes to the neutral bus in the PD panel, and the greeen goes to the ground bus in the PD panel.

I have a chassis ground on the DC ground bus of the PD panel (this is the on I initially forgot to hook up). But, the neither the AC neutral and AC ground busses have a chassis ground. The inverter/charger automatically takes care of bonding the neutral and ground busses together when you are not on shore power, and not bonding them together when you are are shore power, as they will be bonded at the power pedistal, and should only be bonded at one place in the system.

Keep in mind that I am not an electrical engineer or electrician, so take my advice with a grain of salt!

Gary

Haha – I completely understand the caveat! I just wanted to be sure I knew what connection on the DP connected to what, since it’s not always very obvious, and since you had the same device, you were the perfect person to ask.

BTW, I asked you a while ago about the Projecta IDC-25, and I decided to go with it, so I can’t wait to get everything running to see how it turns out. It’s very compact, and very sturdily wired-up, with great instructions, so I’ll let you all know how it goes.

Please let us know how the IDC-25 works out.

Gary

Hi Gary, I’m close to finishing our electrical system and I have a question about the alternator charging of the house batteries. You have a 50 amp breaker at the house battery and it looks like you used a 100 amp mega fuse at the van battery. with the 50 amp breaker that mega fuse will never blow. what am I missing? I’m tempted not to install any fuse at the van battery since the circuit is already protected by the 50 amp breaker. please give me your feedback on this.

Hi Rick,

When you have current sources (batteries) on both ends of the wire as you do with the wire that goes from van battery to house battery, you need fuses on both ends. Each fuse should be as close to its battery as possible.

Reason for this is if you only have one fuse, and the wire shorts to ground anywhere along the wire, you will have a short circuit directly to ground from one of the two batteries. You need the fuse on each end (close to battery) to protect the wire.

I use that smaller breaker on the house battery end so that I will be alerted if the charging current goes above 50 amps. The battery manufacturer says battery life for my batteries will be shortened for high charging currents.

Hope that explains it?

Gary

Gary, I’ve read through this twice now but I still don’t understand clearly what you’re doing with the bare ground of the Romex on the 12v circuits. They’re totally useless, functionally, right? Or am I missing something? What do you do with the bare ground on the fixture end?

You say “Seems like I terminated the white and ground wires on the same negative bus on distribution panel. Then a wire connects the negative bus to the common ground connection point I described before.” But what about the fixture end? You join them there too, presumably. But does having two negative/grounds really add anything other than duplication? I assume it beats not using the ground at all, but I’m curious as to the rationale. Too bad thye don’t make two-strand shielded cable like the old days. 🙂

Hi Paul,

As near as I can remember, if the fixture end had a separate frame ground connection, I hooked the bare ground to it. If not, I just did not use it.

In AC wiring, the bare ground wire is to ground the frame or housing of the appliance you connect it to. It does not actually carry in current under normal circumstances — its there to ensure that if the appliance housing gets shorted to the hot wire the ground wire keeps you from getting electrocuted by the hot casing and blows the fuse. While this is not normally done in DC wiring, you could use the ground wire in the same way.

But, I do agree that the bare ground is not really required for the DC circuits, and I guess one approach that I don’t think would have any safety or functionality issues would be to just cut the ground wire off back to the point where you strip the sheathing on the Romex.

Gary

Hey Gary,

Just getting going on our electrical installation and had a few questions. We have the same distribution panel as you – does it need fuses installed for the DC circuits to work?

We also have the same inverter/charger as you and were wondering if it makes any noise while running?

Thanks,

Abby

Hi Abby,

Yes, you will need DC fuses for the panel. These are the cheap, two bladed automotive type fuses.

The inverter/charger makes a very low hum when running — I can’t hear it except when my ear is right next to it.

Gary

Hi George

I looked through all the settings and options I could find on my end to try and find something to unsubscribe you, but no luck.

The nice thing about doing sites with WordPress is that they take care of so many of the details, but can be frustrating when you want more control.

I will try “unapproving” all the posts I can find for you, and maybe the comments system will be smart enough to stop sending you stuff.

The only other things I can think

of:

Go to the WordPress.org forum: https://wordpress.org/support/ and ask the experts there what can be done. I think that whatever can be done is probably on your end, but if I can do something from this end, let me know.

On your email, filter out emails from my site — ie put me on the spam list.